On the journey to excellence, GBOS has never stopped moving forward. Upholding the philosophy of “Innovation drives development, and service creates value,” we are committed to providing the finest intelligent cutting solutions for customers worldwide.

On this 3.15 World Consumer Rights Day, we invite you to discover GBOS’s core strengths—superior product quality and comprehensive after-sales support.

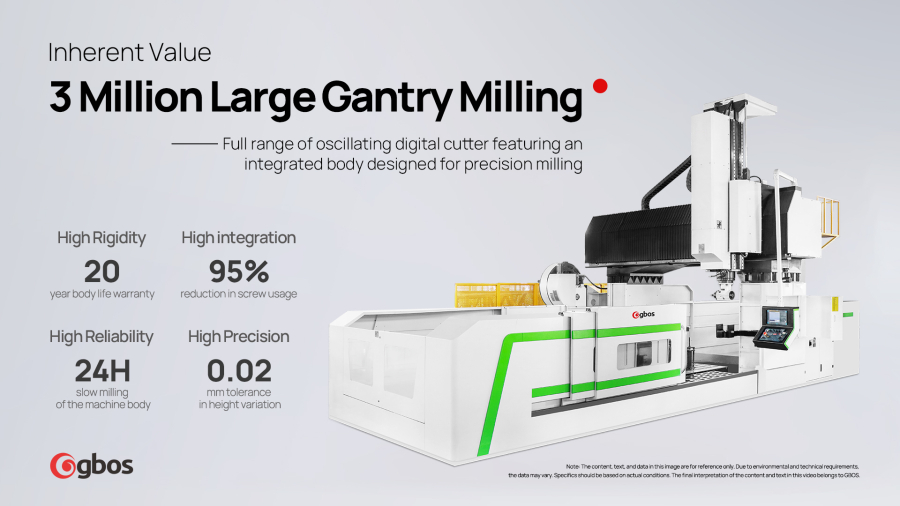

01 Precision Manufacturing | 20 Years of Industrial-Grade Durability.

GBOS machines embody the dedication of countless engineers, with every component and every process meticulously refined. From initial design concepts to final product delivery, we uphold the highest standards of quality control. Throughout the R&D process, we invest extensively in technological innovation and rigorous testing to ensure each machine delivers exceptional performance and stability.

We understand that only with unwavering craftsmanship can we create exceptional products that perfectly meet our customers’ needs, leaving a lasting mark of trust in their hearts.

02 Double the Protection, Reshaping the New Benchmark for Stability and Durability

Double the Protection is a deep commitment to product quality. We meticulously select high-quality materials and create a one-piece molded body, offering significant advantages over traditional aluminum splice bodies.

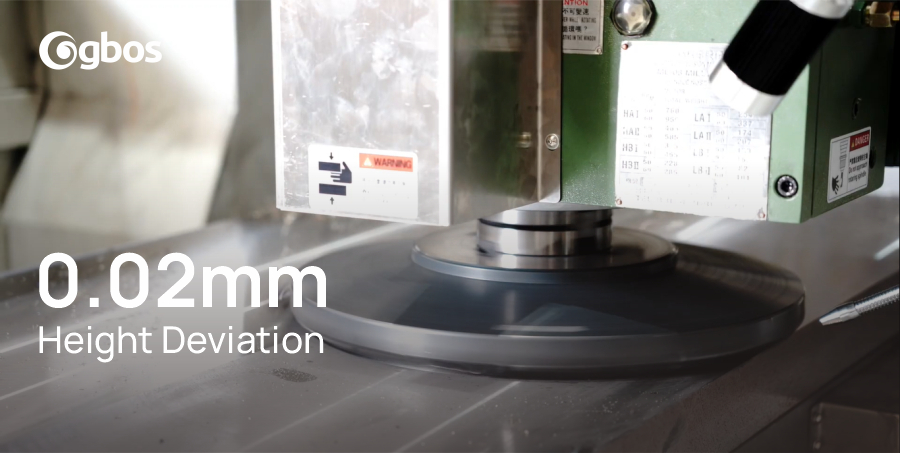

The one-piece molded body eliminates the need for numerous screws used in traditional aluminum spliced bodies, reducing screw usage while significantly enhancing the stability of the machine. With the absence of the looseness risks caused by multiple screw connections, the machine runs more smoothly, effectively preventing precision deviations caused by vibrations, displacement, and other factors, ensuring that the cutting work maintains a consistently high standard.

At the same time, the high-quality materials combined with the one-piece molding process give the machine body exceptional durability. It is resistant to deformation and can withstand long hours of high-intensity workloads, significantly reducing the risk of damage. Whether it’s frequent production tasks or complex working environments, the machine can handle them effortlessly, ensuring reliable performance and truly achieving long-lasting durability and high stability for your production.

03 After-Sales Vanguard, Global Quality Service Without Boundaries

GBOS has a team of professional after-sales engineers who are the guardians of quality and dedicated partners to our clients. As demonstrated in our global inspection tours, these engineers tirelessly travel around the world, providing timely and professional services to our customers.

They possess strong technical expertise, enabling them to quickly diagnose and resolve various equipment issues. At the same time, they approach each customer with a warm attitude, patiently listening to their needs and feedback. Whether it’s equipment installation and debugging, operation training, or ongoing maintenance, the after-sales team provides comprehensive, one-stop services, ensuring that quality service is always within reach.

On the journey of collaboration between GBOS and our global customers, quality and service will never have an endpoint, only new beginnings. In the future, we will continue to uphold craftsmanship and innovation, constantly improving product quality and after-sales service. Together with our global customers, we will forge ahead, creating a smarter, more efficient, and harmonious future.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: